Every operator in Weilly has his own control tool to ensure good quality of his work. Besides the strict self-control carried out by each operator, we use most up-to-date instruments to execute the final quality control, so that optimum quality level can be guaranteed.

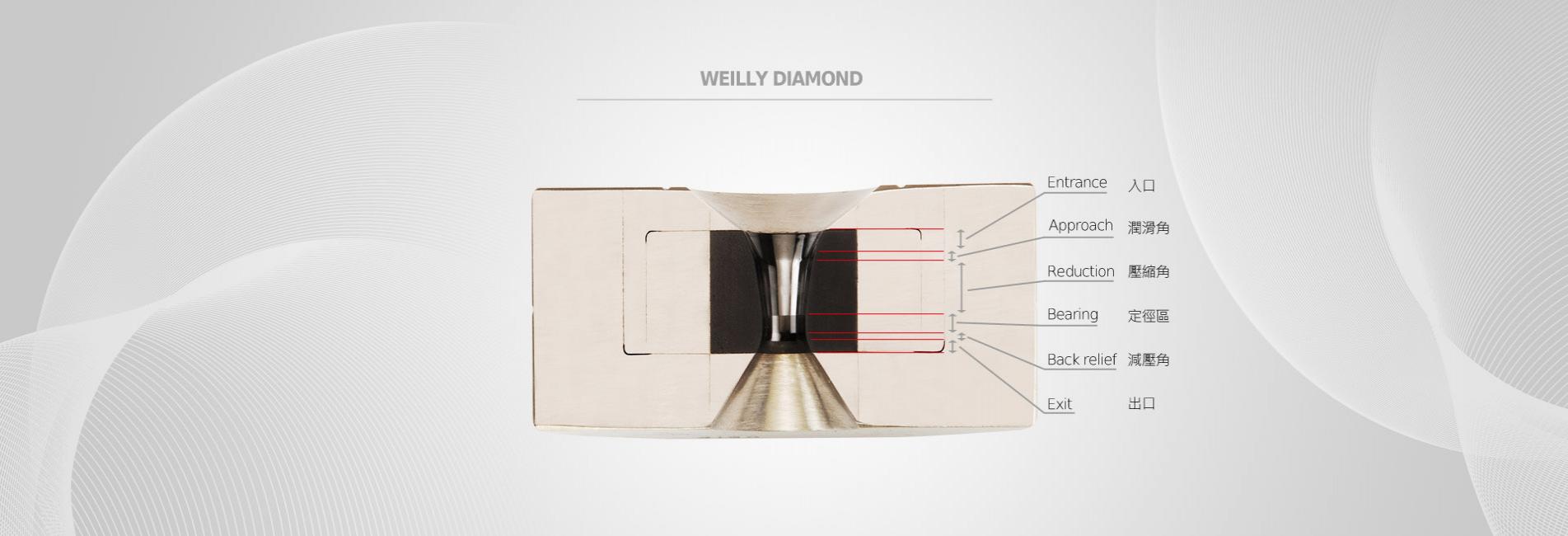

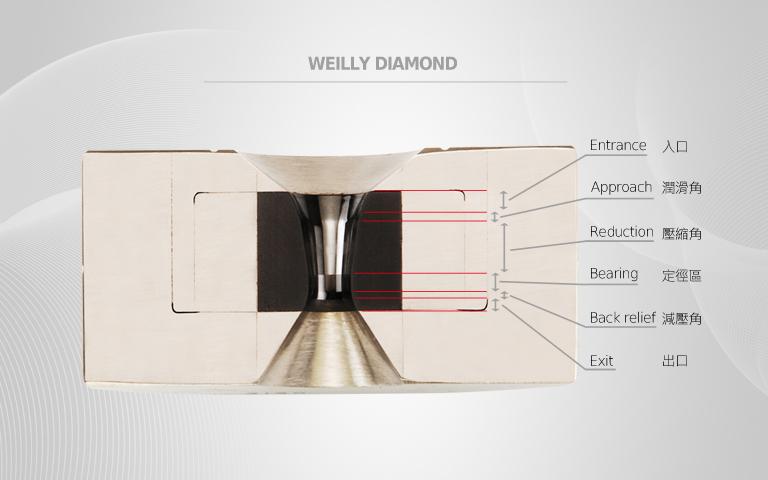

◆ Optical die profiler—Thanks to the innovative Conoptica quality control system, the precision and consistency of die geometry can be regulated to high standard.

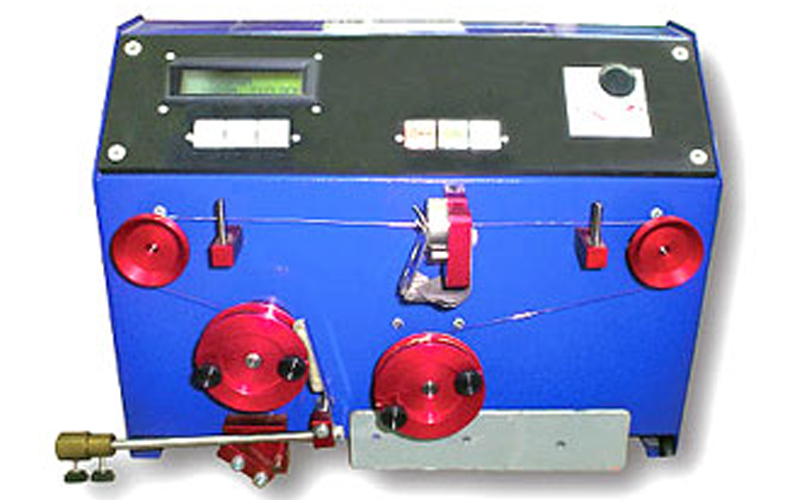

◆ Elongation tester—A matched elongation die set can assist multi-wire drawing machine in achieving maximum drawing speed and reduce wire breaks.

◆ Laser Scan Micrometer—This micrometer with the repeatability within 0.1 micron, works in collaboration with rotating device to measure and monitor diameter and ovality.

◆ Digital OHM Meter—For ultra-fine wire measurement, measure the electric resistance of certain length of wire with known specific resistance. The accurate corresponding wire diameter can be calculated.