Solutions

- HOME

- Solutions

Diamond inspection

Weilly Diamond dies are made of diamond grades close to gem quality, which are checked under a microscope at 100X magnification; any impurities, cracks, or spots can be easily detected and rejected. The orthoscope detects internal stress, as abnormal internal stress can cause die cracking during die manufacturing or the wire-drawing process.

Diamond Setting

Locating the diamond at the exact center of the casing is carried out by a CCD camera-aided positioning device. CCD camera: Charge-coupled Device camera

Metal Powder Filling Machine

Automatically adds sintering reinforcement metal powder in to the dies and ensures consistent weight during reinforcement.

Automatic Sintering Machine- Reinforcement

At Weilly Diamond, we ensure each die is built for strength and longevity through advanced metal matrix reinforcement. Using high-frequency heating, infrared sensors, and an auto-feeder, our automated sintering process evenly heats metal powder to form a stable structure that firmly secures the diamond. This reinforcement helps the die withstand wire impact and extends its service life.

CNC Turning Machine

Automatic turning machines perform front and back cones and two parallel flats with high accuracy. Equipped with digital programming and an auto-feeding system, the process enables high-volume production while ensuring consistent quality and improved processing efficiency.

Centerless Grinding Machine

To ensure precise dimensions and perfect roundness, every die casing at Weilly undergoes centerless grinding. This process tightly controls tolerances within 5 microns, delivering high surface smoothness and consistent outer diameter accuracy—crucial for maintaining the performance and fit of every die we produce.

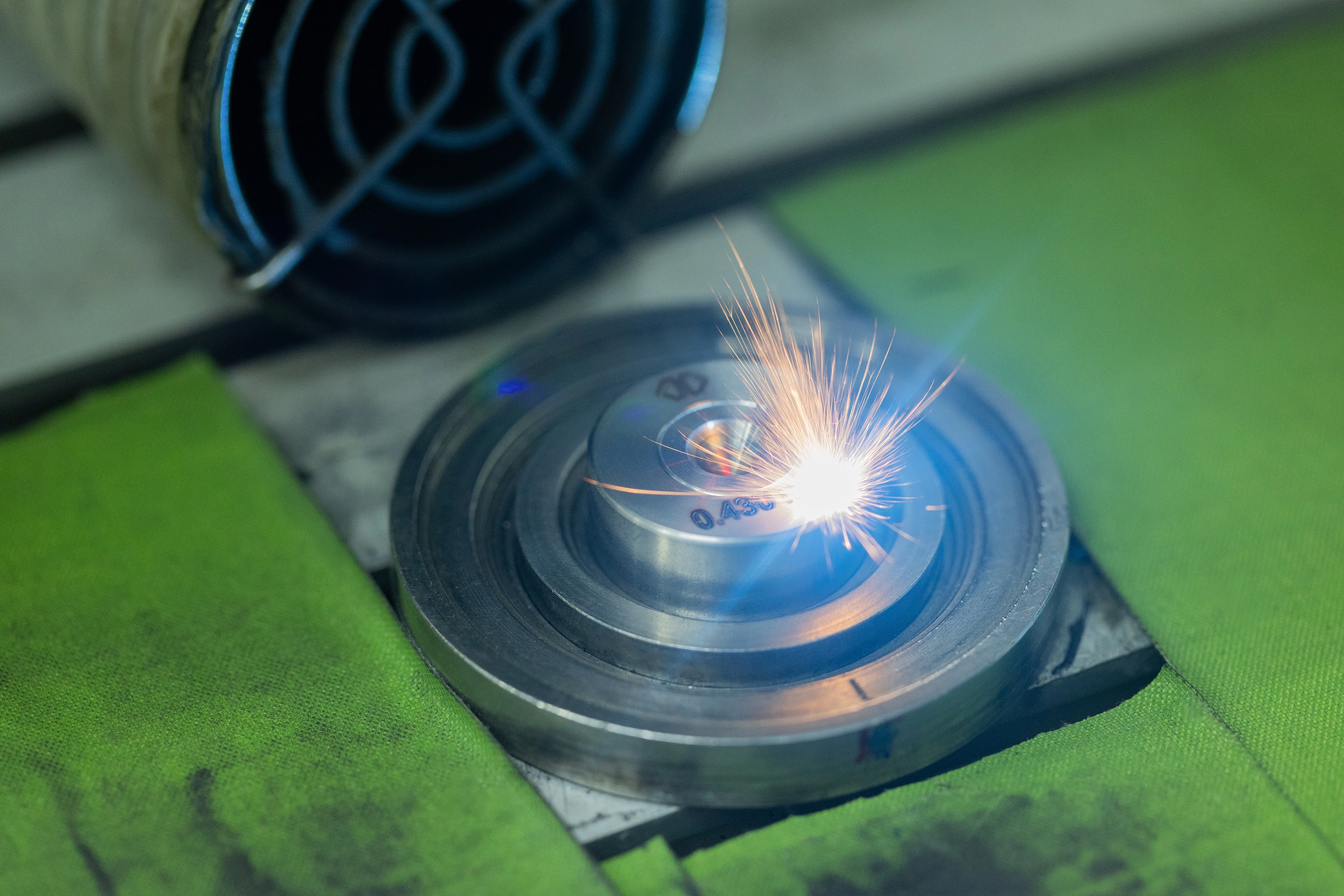

Advanced Laser Die Profile Drilling Machine

Our state-of-the-art laser drilling unit enables high-precision profiling of both single crystal and polycrystalline shaped dies. It performs double-sided drilling—accurately drilling both the entrance and exit—to ensure precise die geometry and consistent profiling. This technology has significantly enhanced the accuracy and repeatability of our shaped dies.

Wire EDM Machine

Utilizes high-precision wire EDM processing for polycrystalline diamond dies. This not only ensures a more accurate die profile but also improves the quality and efficiency for subsequent processing.

Ultrasonic Machine

Over 100 ultrasonic units dedicated to the shaping and precision polishing of both round and shaped diamond dies, ensuring consistency and high surface finish quality.

Wire Lapping Machine- Hole size calibration

Utilizes fine wire to grind and polish the bearing, achieving precise bore dimensions and a mirror-like surface finish essential for optimal wire drawing performance.

Laser Engraving Machine

Uses high-precision laser technology to engrave text, logos, or patterns on die casings, meeting a wide range of custom marking requirements with clarity and accuracy.

完成