Products

Extrusion Tools

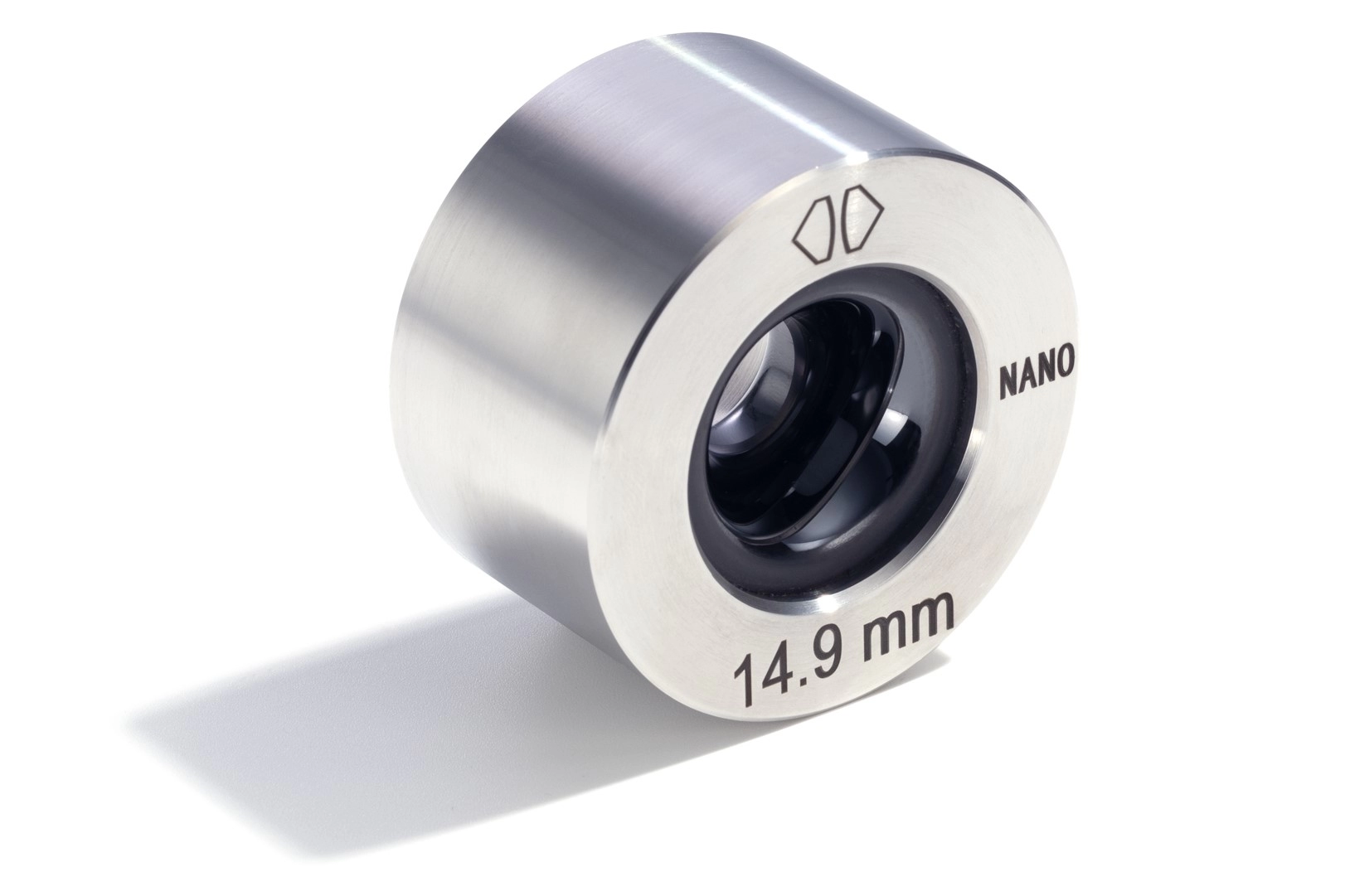

Extrusion tools are used in plastic insulation and coating processes for electrical wires and cables, ensuring smooth and uniform coverings. Typically divided into inner and outer dies, the inner die can be made from materials such as diamond, tungsten carbide, or hardened steel. Weilly's diamond-core extrusion dies deliver superior wear resistance, precision, and durability, lasting much longer than conventional tungsten carbide dies—even under high-speed, continuous production conditions.

Weilly Diamond – Specialists in PCD-Based Extrusion Die Solutions

Weilly Diamond specializes in high-precision extrusion tools built for electrical and communication wire insulation. Our PCD-core inner dies offer superior wear resistance and extended tool life, while our custom multi-hole guide options cater to a variety of production needs.

From plastic-coated copper wire to aluminum insulation lines, our extrusion dies are optimized for performance, reliability, and efficiency in demanding applications.

Features

◆ Precision concentricity control up to 0.005 mm.

◆ Available in PCD, tungsten carbide, and hardened steel.

◆ Supports single and multi-hole configurations.

◆ High resistance to wear and thermal damage.

◆ Customizable sizes and profiles.

Common Applications

◆ Insulation coating for Copper and Aluminum wires.

◆ Plastic sheathing for communication and data cables.

◆High-speed extrusion lines for precision coating.