Products

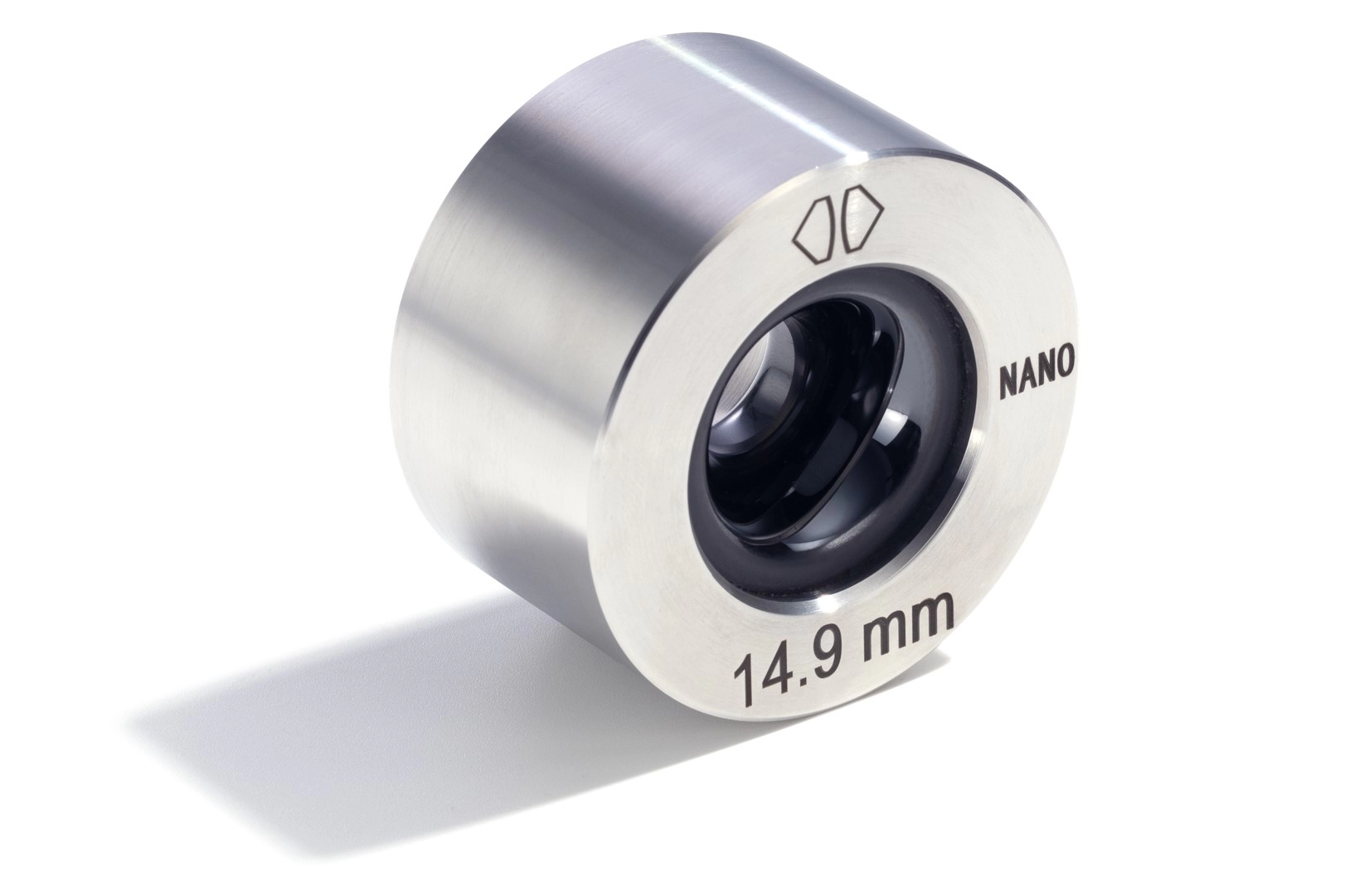

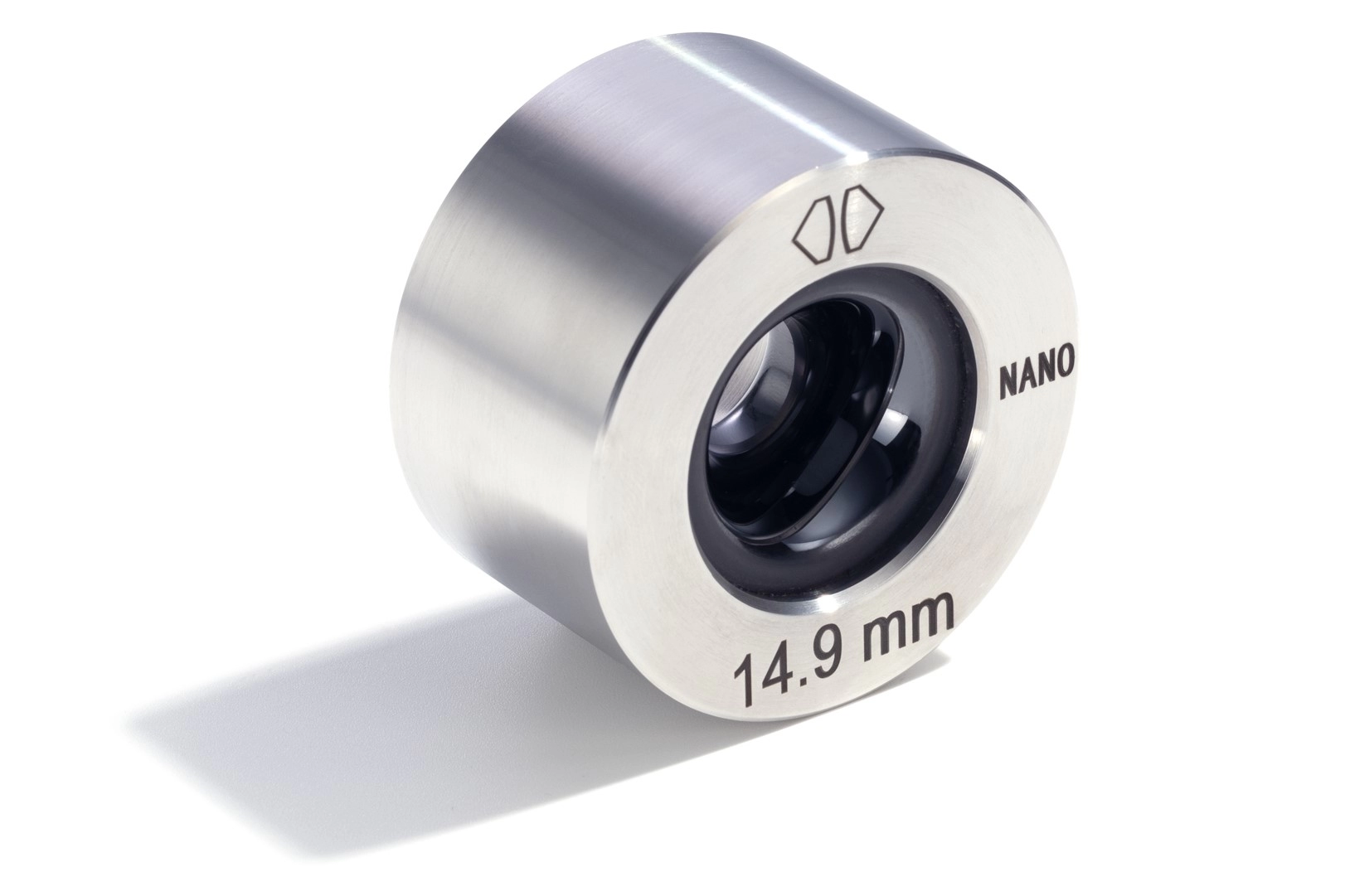

Nano Diamond Coated Dies

Nano Diamond Coated dies feature a nano-diamond layer applied to the bore of tungsten carbide dies, combining exceptional hardness, toughness, thermal conductivity, and lubricity. Weilly's advanced coating dramatically reduces friction—up to ten times more effective than conventional diamond dies and a hundred times more than standard TC dies—ensuring smoother wire flow and superior surface finish.

Weilly Diamond – Innovation Leader in Nano-Coated Die Solutions

At Weilly Diamond, we apply cutting-edge nano-diamond coating technology to our precision-engineered tungsten carbide dies, achieving unmatched drawing efficiency and die life extension. Our Nano Diamond Coating Dies are built for demanding industrial applications in power cable, automotive, and electrical component manufacturing, where surface finish, electrical conductivity, and durability are essential.

With strict in-house quality control and die geometry optimization, Weilly provides reliable, energy-efficient drawing tools trusted by manufacturers worldwide.

Features

◆Nano-diamond coated die hole for ultra-low friction.

◆Superior surface finish with minimal burrs.

◆Exceptional wear resistance and thermal stability.

◆Enhances electrical conductivity and reduces energy loss.

◆Ideal for medium to large wire sizes and high-speed drawing.

Common Applications

◆Medium to large Copper and Aluminum wire drawing.

◆High-performance conductor production.

◆Automotive, telecom, and electrical component wiring.

◆Energy-efficient wire processing in high-volume lines.